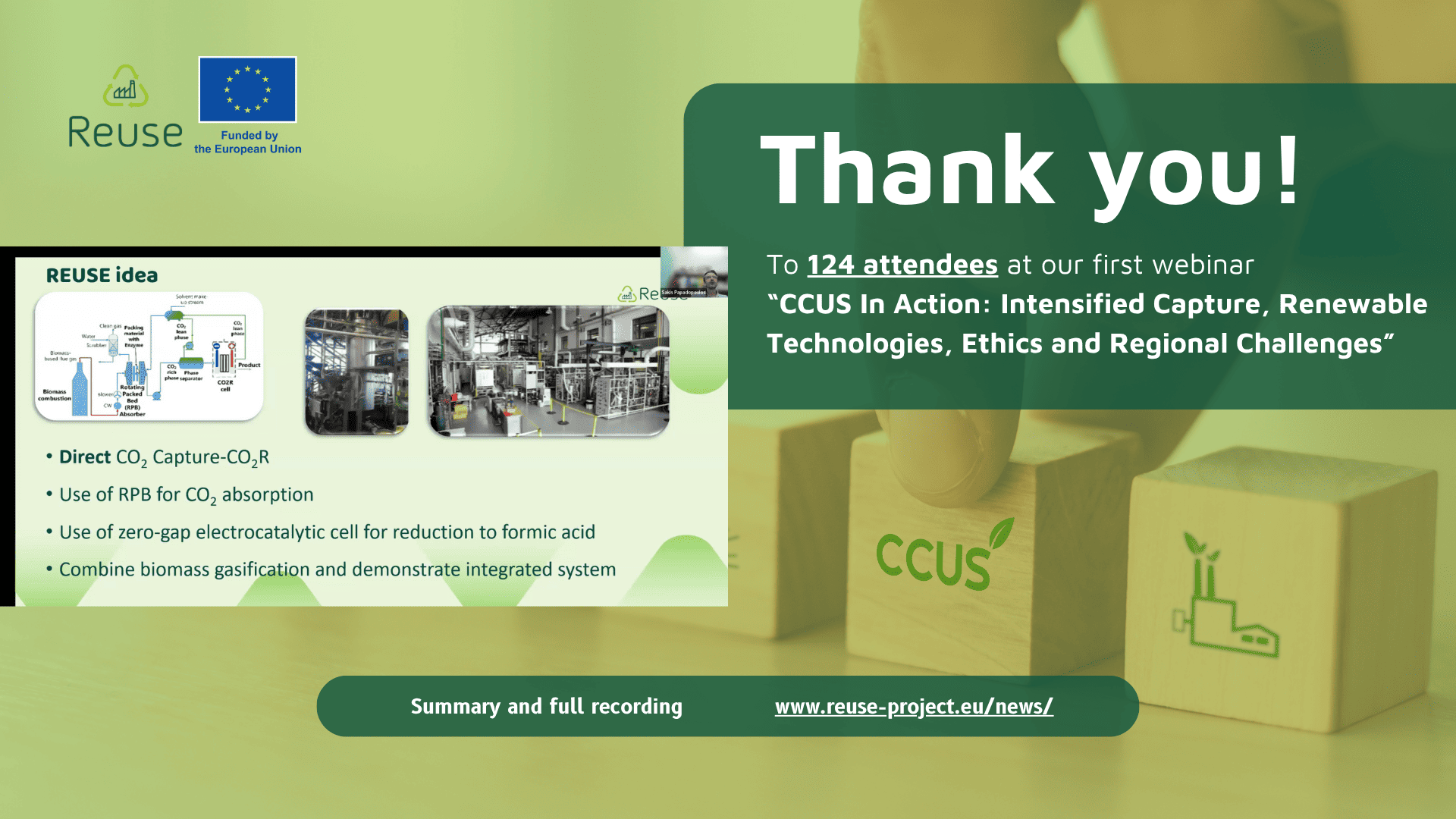

The REUSE Project successfully held its first public webinar on Thursday, 22 May 2025, titled “CCUS In Action: Intensified Capture, Renewable Technologies, Ethics and Regional Challenges”. This event marked REUSE’s first public engagement since the project’s launch under the Horizon Europe Programme in October 2024.

The webinar generated strong interest with 242 registration and 124 attended, achieving a 51% attendance rate 51% – 11% above expectations.

Dr. Athanasios Papadopoulos (Centre for Research and Technology-Hellas CERTH, Greece and REUSE Project Coordinator) opened the webinar by introducing the REUSE project, which focuses on intensifying carbon capture and utilization for biogenic emissions. Technologies used by the project were highlighted, including solvent-based absorption, biomass gasification and electrocatalytic systems. The project uniquely integrates CO₂ capture with electrocatalytic reduction, converting CO₂ directly into valuable chemicals like formic acid using renewable energy. Innovations include phase-change solvents, enzyme-enhanced materials, and zero-gap electrochemical cells. It also explores biomass gasification for sustainable CO₂ sources. REUSE aims to deliver a compact, efficient, and cost-effective CCUS solution to support decarbonization and circular carbon use in line with EU climate goals.

Next, Prof. Jonathan Lee (University of Newcastle, United Kingdom) explored the urgent role of CCUS in climate mitigation, citing Europe’s 2022 emissions of 3.6 Gt CO₂e. Post-combustion solvent capture remains the most proven method, though it’s energy-intensive. He highlighted the Rotating Packed Bed (RPB) system as a breakthrough in compact, cost-efficient CCUS deployment—essential for reaching Paris Agreement targets.

Dr. Stella Balomenou (CERTH, Greece) presented advancements in electrochemical CO₂ reduction as a sustainable method for converting emissions into fuels and chemicals. The presentation covers low- and high-temperature processes, particularly solid oxide electrolysis, which offers high efficiency and integration potential. CO₂ can be converted into formic acid, methanol, and syngas, aiding clean energy storage and industrial reuse. Challenges include low catalyst efficiency, high energy demand, and slow kinetics. Advancements in catalysts, modular reactor design, and renewable energy integration are key research directions. The presentation underscores CO₂ as a valuable feedstock, promoting circular economy principles within Horizon Europe REUSE project.

Milica Milić, PhD (Novonesis, Denmark) addressed the ethics of enzymatic carbon capture, balancing innovation with responsibility. She emphasizes principles like fairness, harm prevention, and respect for rights. Novonesis offers biosolutions for different industries, among which is also carbon capture facilitated using enzymes (proteins that speed up chemical reactions). Enzymes offer high efficiency, low energy use, and scalability, and enzymatic carbon capture can be easily integrated into existing industrial systems. However, enzymes may trigger respiratory allergies if inhaled, necessitating strict occupational safety measures. Novonesis follows ethical standards and uses 100% renewable energy in operations. The approach reflects a sustainable, health-conscious method of reducing industrial carbon emissions while aligning with global climate goals.

Last but not least, Martha Bissmann (CES clean energy solutions GesmbH, Austria) highlighted the critical role of CCUS in helping Eastern European countries meet EU climate goals. The region accounts for 25% of EU emissions, with Bulgaria as a case study. Although EU frameworks support CCUS, many countries – including Bulgaria – lack national strategies or infrastructure. The flagship ANRAV project in Bulgaria, shared by Martha, aims to capture CO2 from cement production and store it offshore, potentially cutting 95% of emissions from one plant. Success depends on transposing EU law into national policy, developing infrastructure, and securing funding. Among the ending remarks, Martha highlighted again that the aim of REUSE project is to accelerate these transitions and promote sustainable, circular carbon use.

The webinar served as an interactive forum, with live Q&A sessions fostering knowledge exchange between attendees and speakers. The list of questions and live answers are attached in the following as annex.

ETA Florence Renewable Energies, a REUSE consortium partner, ensured smooth coordination as leader of the project’s Communication, Dissemination, and Exploitation work package.

Annex – Q&As during the webinar:

Q1: How often has the Enzyme to be replaced? are these vulnerable to impurities in the off-gas stream? (SO2, NOx etc.)

Answer: The enzyme would probably be vulnerable to impurities, but technologies for impurity removal will be in place anyway, even in conventional capture processes that do not use enzymes. The enzyme may maintain activity for several days, research efforts are focused on developing enzymes that are resilient and may operate for long. This is a research field that is receiving a lot of attention.

Sub-Q: And is there a lower limit of CO2 concentration needed to actually capture it with this technology? So if I would have an off-gas out of a biomass combustion engine there would be a concentration around 10-15%.

Answer: It could work for gases with concentrations down to 3.5-4% CO2. This is what a typical natural gas power plant would emit.

Q2: From the economic feasibility point of view, how is enzyme preferred? And can be regenerated the enzyme?

Answer: These are very valid and open questions. The project will hopefully provide new insights to this end. We just don’t have the answers yet.

Q3: How were these Emin values calculated? based on what? Shouldn’t it be based on the CO2 purity in the flue gas which differs from one process to another? Also, how can I know the Emin for capturing CO2 from powerplants?

Answer: The Emin calculations were based on the minimum thermodynamic work for separation, however that formula only does the calculation for one mole of CO2-gas mixture. This number has to be multiplied by a factor that accounts for the concentration of CO2 in the gas.

Sub-Q: For the Emin calculation, is there a specific generalized formula used to calculate the thermodynamic work for separation for any industry? Or was it calculated based on simulations/real-world data? Also, can powerplant carbon capture Emin be calculated similarly?

Q4: Is the process technology for using enzyme matured?

Answer: It is still at low technology readiness for solvent-based absorption systems.

Q5: is there already an existing pilot plant in operation?

Answer: Some tests have been done in small (lab) scale pilot plants, but with columns ad with thermal regeneration, No with the Rotating Packed bed technology that we are doing or with the electrochemical reduction.

Q6: For CO2-EOR, is utilising CO2 from industrial flue gases practical and feasible if this flue gas has a CO2 purity of 17%?

Answer: EOR is not done using industrial flue gases because you would have to compress and inject a lot of nitrogen, which does not dissolve in hydrocarbons.

Sub-Q: what if nitrogen was separated and the CO₂ is now at a high purity (>95%), is it economically feasible to actually treat the flue gas to this purity percentage for EOR?

Q7: Is there any known developed/implemented solutions or test facilities using ICCU (integrated CO2 capture and methanation process with external H2 input, all done in one reactor)?

Answer: Plants for thermo-catalytic methanation probably exist, but I am not sure if they are integrated with CO2 capture.

Q8: Is there the possibility to get the presentations afterwards?

Answer: Some presentation details will be shared, while some details remained unsharable due to data protection issue. Please follow our LinkedIn page and website, we will update soon the sharable insights after the webinar today.

Q9: Will the recordings be shared after?

Answer: Yes.

Q10: A question for Jonathan Lee. Is it possible or has the rotating pack bed speperation been considered in a maritime environment, for example on ships?

Answer: Yes it has. Carbon Clean Solutions and Samsung announced a collaboration in late 2023 (https://www.theengineer.co.uk/content/news/carbon-clean-and-samsung-engineering-developing-carbon-capture-for-ships/). I have been asked by shipping companies about it quite a few times. Using an RPB for capturing CO2 from marine engines is technically feasible, but on a ship finding the energy required for the CO2 capture process and space to store captured CO2 are bigger issues.

Q11: A question for Milica: where you see the most substantial differences in terms of ethical considerations when specifically comparing enzymatic to other/”conventional” carbon capture technologies?

Answer: I would say that when it comes to the process the ethical considerations are more or less the same. However, I would add that one needs to consider the production of enzymes, waste desposal, and the safety precautions when using the enzymes. But I would say most of this lies with the manufacturer, who is also responsible for providing information on how to handle their product.

Watch the full recording:

Downloadable presentations from the webinar:

CO2 as a Raw Material electrochemical processes to produce fuels and chemicals